Quality Injection Molding Manufacturing

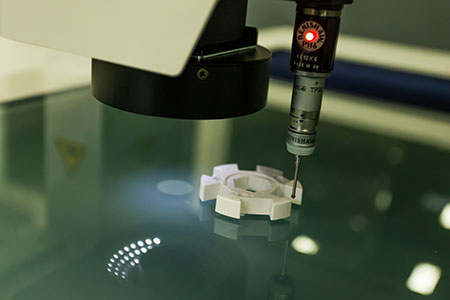

The quality system employed at Blue Ridge Molding is certified to ISO 9001:2015. Quality and control plans are customized to ensure parts meet customer requirements and expectations. Our quality inspectors monitor processes and dimensional requirements 24 hours a day utilizing an array of calibrated gauges, measuring tools and scales. In addition, dimensional requirements are checked and charted using a state of the art CMM machine with vision and probe capabilities.

Automated, closed material handling systems protect materials from exposure to contamination.

Each product that is produced at Blue Ridge has its own unique “Job Packet” that defines quality expectations of the customer, illustrations of nonconforming product, machine settings for process consistency, packaging information, training records and color standards. Advance Product Quality Planning (APQP) helps to insure repeatability and that a customer’s product will be made to its expectations each time the product is produced. We strive to promote a culture of quality throughout all phases of our operations.